Semiconductor Jobs

Finding the people that are innovating the future

With the rise of India as a semiconductor talent powerhouse, we embrace the mission of equipping organizations with the brightest minds in semiconductor technology, from VLSI design to advanced chip manufacturing and packaging. Our approach is deeply rooted in understanding your company’s goals and delivering skilled professionals ready to lead the industry forward.

Whether you’re building cutting-edge fabs or driving next-gen innovations, our specialized expertise and global connections ensure that every hire makes an impact. Together, we’re shaping a future where India fuels the global semiconductor revolution, one mind at a time.

Our approach

Headhunters

You want the best talent, not just the best available. We leverage our vast network and extensive database, to proactively source and connect you with exceptional passive candidates.

Specialists

We speak your language and are deeply embedded in the electronics industry, possessing a nuanced understanding of the challenges and talent landscape.

Technology

Find Specialized Talent for the Semiconductor Industry – From Cleanroom Operators to Advanced Chip Designers. Click to Explore Skilled Candidates in Every Niche!

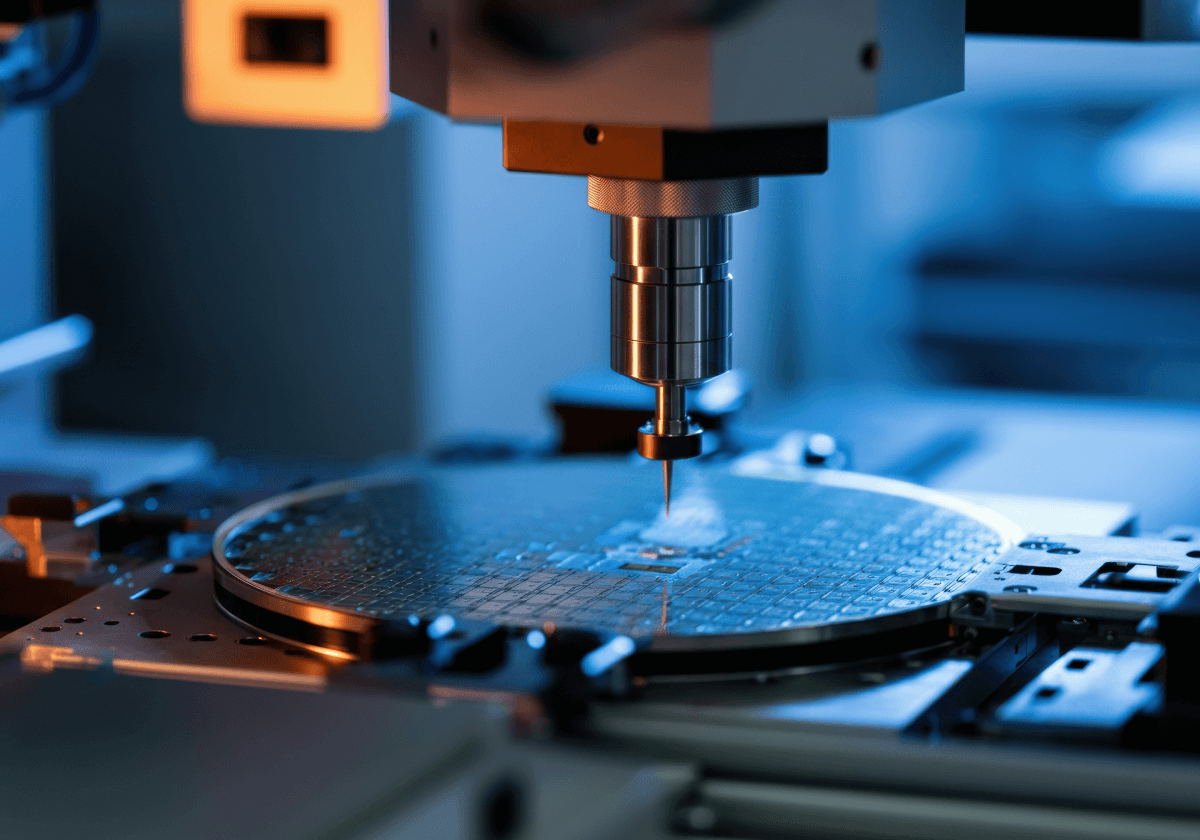

Cleanroom Manufacturing Technician

Skills Offered

Expertise in wafer handling, maintaining high cleanliness levels.

Education/Certifications Required

Diploma/B.Tech (Electronics/Mechanical); Cleanroom Certification.

Why Critical

Ensures defect-free production crucial for yield improvement.

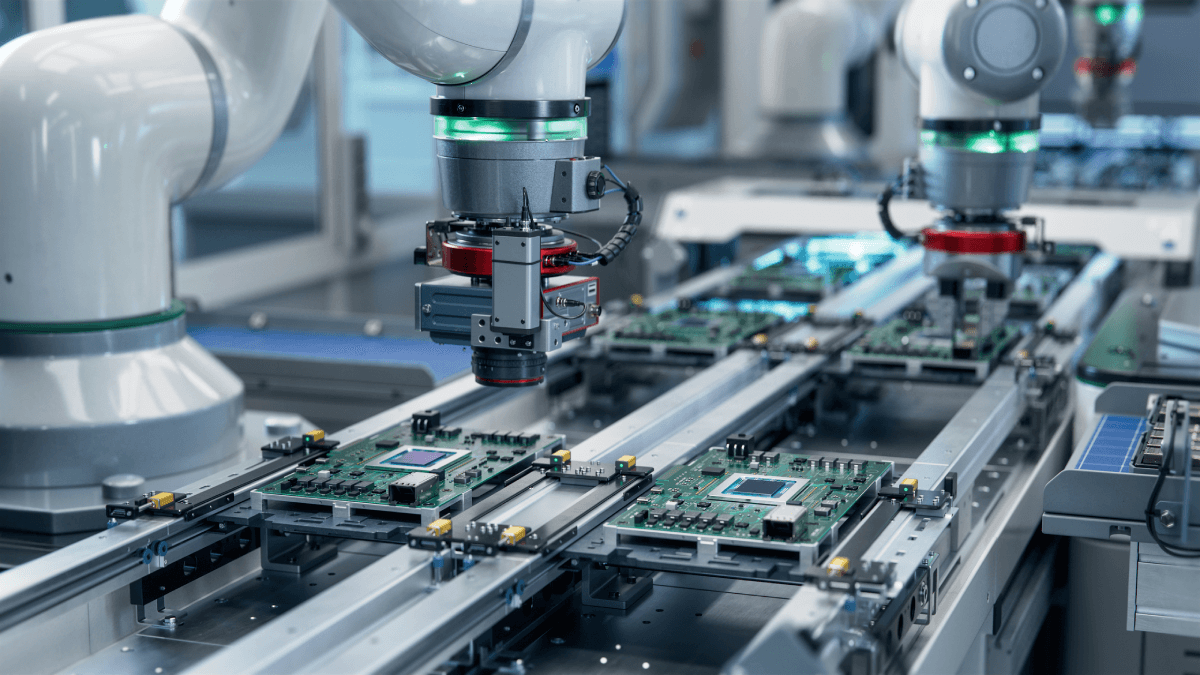

Packaging and Assembly Operators

Skills Offered

Knowledge of IC packaging, wire bonding, precision defect inspection.

Education/Certifications Required

ITI/Diploma; ISO Inspection Certification (Optional).

Why Critical

Protects and integrates semiconductor devices in the final manufacturing stage.

Process Engineers

Skills Offered

Optimization of processes like deposition/etching for production efficiency.

Education/Certifications Required

B.Tech/M.Tech (Materials Science, Semiconductor Physics); Process Certification (from SEMI or equivalent).

Why Critical

Drives productivity at fabs through yield enhancement.

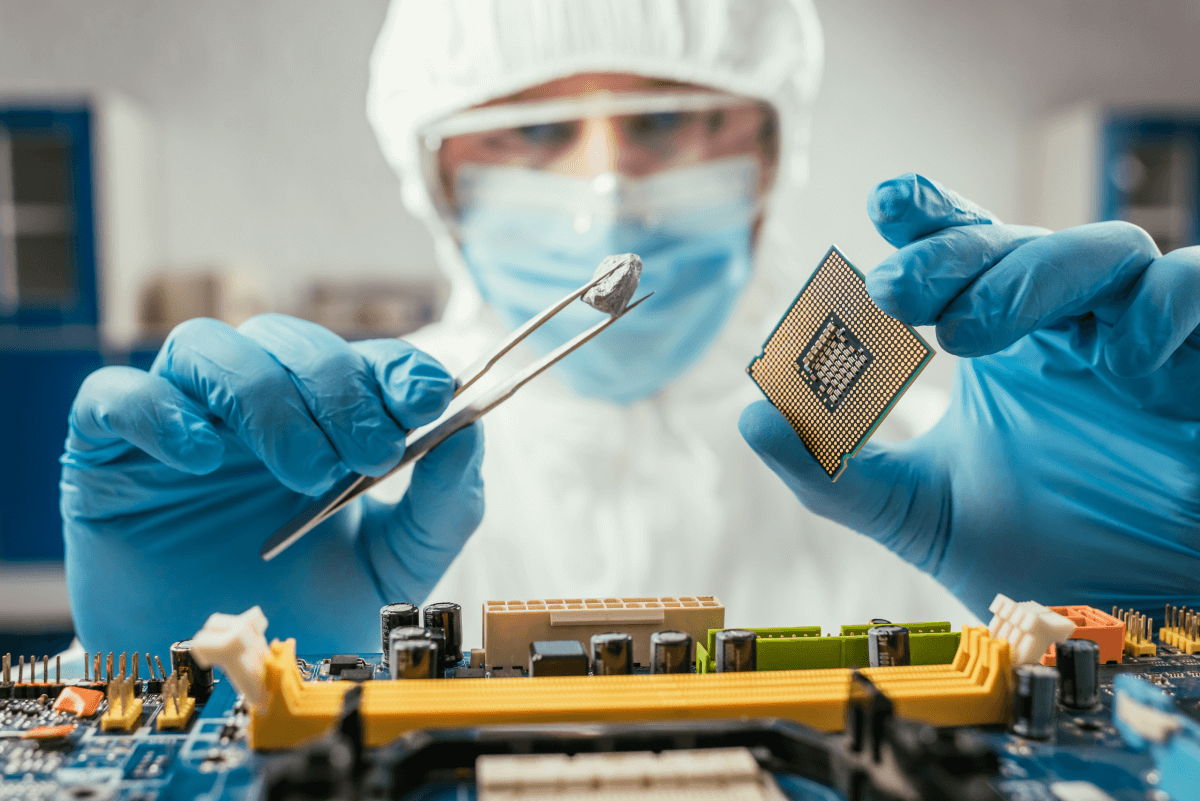

Design Engineers

Skills Offered

Circuit layout design and VLSI expertise.

Education/Certifications Required

B.Tech/M.Tech (ECE, VLSI); Software Certification (Synopsys, Mentor Graphics).

Why Critical

Central to chip innovation and developing AI/IoT circuits for future technologies.

Test Engineers

Skills Offered

Chip diagnostics, error troubleshooting using automated testing equipment.

Education/Certifications Required

Diploma/B.Tech (Electronics); Certification in ATE (Automatic Test Equipment, e.g., Advantest tools).

Why Critical

Ensures chip quality by identifying errors before mass production.

Equipment Maintenance Technicians

Skills Offered

Maintenance of OEM tools like ASML wafer steppers, Lam plasma etchers.

Education/Certifications Required

ITI/Diploma; Hands-on OEM Certifications (ASML, Lam, Applied Materials).

Why Critical

Supports smooth fab operation and reduces equipment downtime.

Facilities Engineers

Skills Offered

HVAC systems management, ultrapure water treatment, chemical delivery.

Education/Certifications Required

B.Tech/Diploma (Mechanical/Environmental); Safety/ISO Certifications.

Why Critical

Critical for sustaining unswerving fab infrastructure for semiconductor manufacturing.

IT Support Engineers

Skills Offered

Expertise in MES (Manufacturing Execution Systems), cybersecurity, automated systems.

Education/Certifications Required

B.Tech (IT/CS); MES Certifications (example Siemens MES or FabTech MES Certifications).

Why Critical

Semiconductor manufacturing depends heavily on automated processes and IT-driven workflows.

Quality Control Specialists

Skills Offered

Proficient in QA tools like SEM (Scanning Electron Microscopes), defect spotting.

Education/Certifications Required

Diploma/B.Tech; Advanced Quality Certification (e.g., ISO-certified QA standards).

Why Critical

Maintains high product quality and minimize failures in global supply chains.

Failure Analysis Engineer

Skills Offered

Expertise in post-production testing and debugging physical-based chip challenges using systems like TEM (Transmission Electron Microscopy).

Education/Certifications Required

B.Tech/M.Tech (Semiconductor Physics, Materials); Certifications in Characterization Methods like TEM/SEM Analysis.

Why Critical

Resolves yield-reducing physical issues by thorough diagnostic imaging analysis, critical in advanced fabs.

EHS Specialist (Environment, Health, and Safety)

Skills Offered

Inventory, chemical handling, and international logistics compliance.

Education/Certifications Required

MBA (Supply Chain), Diploma (Imports/Exports); Certifications in Supply Chain Software or Compliance Standards.

Why Critical

Efficiently supports high-demand just-in-time production models at fabs.

R&D Engineer - Materials & Devices

Skills Offered

Researching and improving semiconductor materials, devices, and nanotechnology processes.

Education/Certifications Required

M.Tech/Ph.D. in Semiconductor Materials/Physics; Experience with R&D-focused labs.

Why Critical

Drives innovation in next-generation chips (e.g., scaling to 2nm nodes or below).

Photomask Technician

Skills Offered

Skilled in photolithography equipment and creating precise photomasks for semiconductor chips.

Education/Certifications Required

ITI/Diploma in Electronics; Training in Lithography/Mask Making.

Why Critical

Photomasks are critical components for wafer imaging in advanced lithography processes.

AI Hardware Engineers

Skills Offered

Developing AI-accelerated semiconductor designs, incorporating GPUs, TPUs, and high-bandwidth memory devices.

Education/Certifications Required

B.Tech/M.Tech (AI-Accelerated Hardware, Computer Architecture); Certification (e.g., NVIDIA AI Hardware Labs).

Why Critical

AI hardware is a rapidly growing sub-industry that powers future technologies from autonomous cars to deep learning.

Automation Engineer

Skills Offered

Automating semiconductor production tools and processes using robotics/AI.

Education/Certifications Required

B.Tech/Diploma (Electrical/Electronics); Training in Robotics Process Automation (RPA).

Why Critical

Fabs are increasingly automated, requiring skilled experts to optimize automation workflows.