Shape the Future with a Career in Power Electronics

Where Talent Meets Technology to Drive Innovation in Power Electronics

Power Electronics Jobs at Best NanoTech

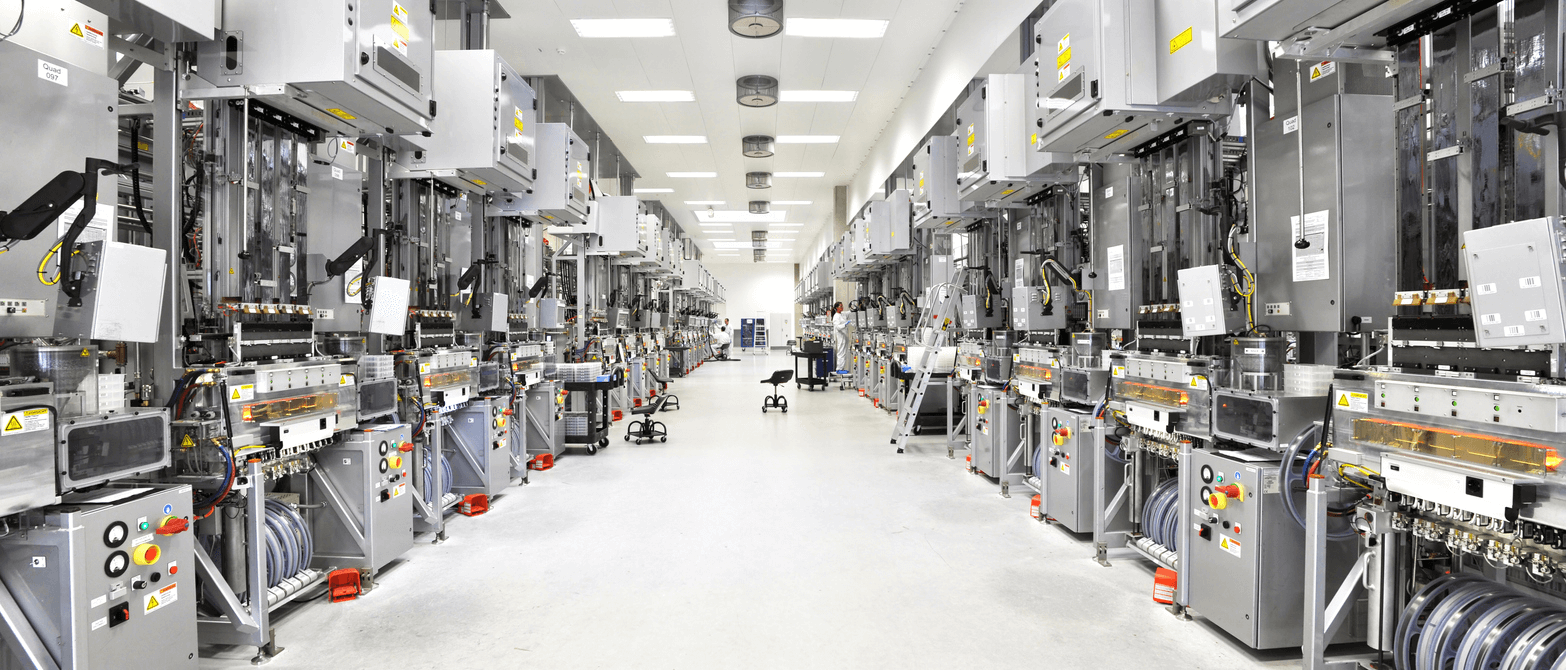

At Best NanoTech, we’re energizing the future by connecting exceptional talent with groundbreaking opportunities in power electronics. From embedded system design to PCB layout, analog/digital circuit development, and IoT integration, we specialize in sourcing experts who drive innovation across industries like renewable energy, electric vehicles, aerospace, and industrial automation.

With a deep understanding of the power electronics landscape, we partner with organizations worldwide to deliver skilled professionals ready to tackle the challenges of energy efficiency and advanced technology. Whether you’re building cutting-edge systems or advancing sustainable solutions, our expertise ensures every hire sparks progress.

Let Best NanoTech help you power up your career or build transformative teams in this dynamic and rapidly growing field.

Our approach

Headhunters

Specialists

Technology

Find Specialized Talent for the Power Electronics Industry – From Embedded System Designers to IoT Innovators. Click to Explore Skilled Candidates Driving Energy Efficiency and Innovation!

Power Electronics Design

Skills Offered

Expertise in wafer handling, maintaining high cleanliness levels.

Education/Certifications Required

Diploma/B.Tech (Electronics/Mechanical); Cleanroom Certification.

Why Critical

Ensures defect-free production crucial for yield improvement.

Power IC Design & Development

Skills Offered

Knowledge of IC packaging, wire bonding, precision defect inspection.

Education/Certifications Required

ITI/Diploma; ISO Inspection Certification (Optional).

Why Critical

Protects and integrates semiconductor devices in the final manufacturing stage.

Motor Control & Drive Systems

Skills Offered

Optimization of processes like deposition/etching for production efficiency.

Education/Certifications Required

B.Tech/M.Tech (Materials Science, Semiconductor Physics); Process Certification (from SEMI or equivalent).

Why Critical

Drives productivity at fabs through yield enhancement.

Wide Bandgap Semiconductors

Skills Offered

Circuit layout design and VLSI expertise.

Education/Certifications Required

B.Tech/M.Tech (ECE, VLSI); Software Certification (Synopsys, Mentor Graphics).

Why Critical

Central to chip innovation and developing AI/IoT circuits for future technologies.

Power Module Engineering

Skills Offered

Chip diagnostics, error troubleshooting using automated testing equipment.

Education/Certifications Required

Diploma/B.Tech (Electronics); Certification in ATE (Automatic Test Equipment, e.g., Advantest tools).

Why Critical

Ensures chip quality by identifying errors before mass production.

Energy Storage and Battery Management Systems (BMS)

Skills Offered

Maintenance of OEM tools like ASML wafer steppers, Lam plasma etchers.

Education/Certifications Required

ITI/Diploma; Hands-on OEM Certifications (ASML, Lam, Applied Materials).

Why Critical

Supports smooth fab operation and reduces equipment downtime.

Power Systems & Architecture

Skills Offered

HVAC systems management, ultrapure water treatment, chemical delivery.

Education/Certifications Required

B.Tech/Diploma (Mechanical/Environmental); Safety/ISO Certifications.

Why Critical

Critical for sustaining unswerving fab infrastructure for semiconductor manufacturing.

Testing & Validation

Skills Offered

Expertise in MES (Manufacturing Execution Systems), cybersecurity, automated systems.

Education/Certifications Required

B.Tech (IT/CS); MES Certifications (example Siemens MES or FabTech MES Certifications).

Why Critical

Semiconductor manufacturing depends heavily on automated processes and IT-driven workflows.

Thermal & Mechanical Design

Skills Offered

Proficient in QA tools like SEM (Scanning Electron Microscopes), defect spotting.

Education/Certifications Required

Diploma/B.Tech; Advanced Quality Certification (e.g., ISO-certified QA standards).

Why Critical

Maintains high product quality and minimize failures in global supply chains.

Manufacturing & Supply Chain

Skills Offered

Inventory, chemical handling, and international logistics compliance.

Education/Certifications Required

MBA (Supply Chain), Diploma (Imports/Exports); Certifications in Supply Chain Software or Compliance Standards.

Why Critical

Efficiently supports high-demand just-in-time production models at fabs.

Field Applications & Customer Support

Skills Offered

Expertise in post-production testing and debugging physical-based chip challenges using systems like TEM (Transmission Electron Microscopy).

Education/Certifications Required

B.Tech/M.Tech (Semiconductor Physics, Materials); Certifications in Characterization Methods like TEM/SEM Analysis.

Why Critical

Resolves yield-reducing physical issues by thorough diagnostic imaging analysis, critical in advanced fabs.

Business Development & Sales

Skills Offered

Inventory, chemical handling, and international logistics compliance.

Education/Certifications Required

MBA (Supply Chain), Diploma (Imports/Exports); Certifications in Supply Chain Software or Compliance Standards.

Why Critical

Efficiently supports high-demand just-in-time production models at fabs.